Many customers want to reliably dissipate heat without sacrificing silent operation when designing a fanless industrial mini PC. Balancing passive and active cooling strategies in industrial mini PCs is essential for their performance and durability. Therefore, we identify standard cooling requirements in our designs, where ambient temperatures can reach over 60°C. Next, we place the components that form the primary heat dissipation paths. Finally, we maintain optimal operation through the use of active technologies, dynamic thermal management algorithms, and optional auxiliary air flow devices.

Characterizing Thermal Load and Environmental Constraints for Fanless Industrial Mini PC

Based on our experience designing fanless industrial mini PCs, accurately characterizing the system’s thermal load is the first step in an effective cooling design. For example, during the design process, we measure the TDP of the CPU and GPU at peak load. Additionally, we consider other heat sources, such as DC-DC converters and storage modules. And it is equally important to consider the actual application environmental constraints, where the industrial environment may expose the mini PC to dust, moisture, or corrosive media, making open-air convection cooling impossible. We perform thermal imaging and use data loggers to map chassis temperature gradients, ensuring our designs withstand worst-case thermal conditions.

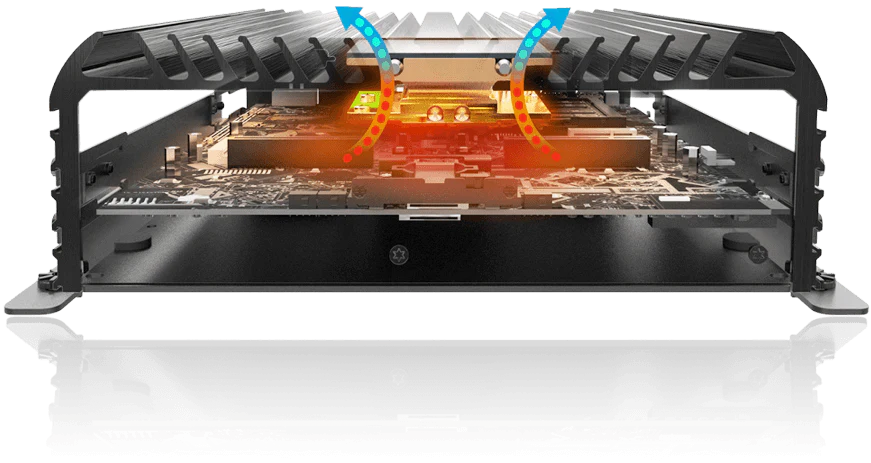

Optimizing Passive Cooling through Chassis Design

Another hallmark of the fanless industrial mini PCs is their passive cooling capabilities, made possible by our carefully designed chassis architecture. During the design process, large surface area heat sinks are incorporated into the aluminum housing, typically doubling the external area of a flat panel. As a result, natural convection and radiation effectively dissipate heat without the need for moving parts. Grade 6063 anodized aluminum is used due to its high thermal conductivity and corrosion resistance, ensuring long-term performance. We also purposefully place component modules directly against the chassis wall and use thermal interface materials to maximize thermal conductivity. This passive-first design approach ensures silent, maintenance-free operation for the fanless mini PC product line.

Enhancing Heat Transfer with Advanced Materials

To further advance passive cooling, advanced thermally conductive materials are designed into the fanless industrial mini PC design. For example, we embed vapor chamber heat sinks directly under high-power SoCs to evenly distribute localized heat throughout the chassis. Additionally, we use graphite thermal pads to bridge the gap between components and the enclosure. At the same time, we source phase-change thermal media (TIMs) that optimize thermal conductivity at 100-150°C operating points, reducing thermal resistance by up to 30%. These material innovations enhance passive cooling, allowing our industrial mini PCs to operate reliably in a variety of demanding scenarios, from outdoor kiosks to factory floor controllers.

Active Thermal Management for Fanless Industrial Mini PC

Passive solutions handle steady-state heat, while active thermal management ensures that the system adapts to dynamic workloads. In our fanless industrial mini PCs, we deploy embedded firmware that monitors the temperature of multiple sensors. First, the firmware reads the chassis and CPU temperatures every 50 milliseconds. Then, if the temperature exceeds a predefined threshold, the system adjusts CPU clock speed via dynamic frequency scaling (DFS). At the same time, we configure a multi-level throttling profile that reduces the clock speed in 5% increments to prevent thermal runaway while maintaining responsiveness. This software-driven “active cooling” complements the passive hardware, ensuring consistent performance under fluctuating application loads without the need for physical fans.

Optional auxiliary cooling for extreme conditions

For installation environments where passive and algorithmic cooling may not be enough, such as confined spaces or ambient temperatures above 55°C, our fanless industrial mini PCs also offer optional auxiliary cooling modules. In addition to the core fanless design, we also provide a low-power, brushless microblower to circulate air between the chassis and the heat sink gently. This allows for double the cooling effect in extreme environments. Additionally, we will guide customers in deploying these modules only when environmental testing indicates that thermal stress is sustained, ensuring minimal impact on acoustic comfort and power consumption. This hybrid solution retains the benefits of fanless design while extending the operating range of dedicated applications.

Balancing passive and active cooling

Balancing passive and active cooling in the design of fanless mini PCs requires a layered, holistic approach, including an aluminum chassis with carefully designed heat sinks, advanced thermal materials, embedded firmware for dynamic thermal management, and an optional auxiliary air circulation system for extreme conditions. In actual production, we utilize extensive thermal testing and field feedback to refine each thermal component, ensuring that our industrial mini computer products deliver reliable and long-lasting performance in diverse industrial scenarios.