When we select the right industrial mini pc for your automation project, we understand the unique needs of industrial environments and the specific tasks you need to perform. Unlike regular mini PCs, industrial mini PCs are designed to operate 24/7 in harsh conditions such as extreme temperatures, vibration, dust, and electrical noise. We evaluate the target application’s performance requirements, environmental constraints and integration points during production. By understanding these requirements, we ensure that the selected industrial mini computer meets the technical, mechanical, and operational goals of your project.

Evaluate the processing power and memory requirements of the required industrial mini pc

Processing power and memory capacity are key when selecting an industrial mini pc for automation, where automation software requires stable CPU performance and ample memory. When planning to run complex SCADA applications and real-time analytics, we utilize industrial mini computers equipped with Intel Core i5 or i7 processors, which help minimize latency and ensure the responsiveness of control loops. Additionally, consider future expansion and provide at least 8 GB of DDR4 RAM to support software updates and add-on modules without performance bottlenecks.

The type of storage can also affect the overall responsiveness. SSDs boot and load applications faster, while industrial-grade NVMe SSDs combine speed and vibration resistance. I typically choose an industrial mini PC with dual M.2 slots to implement RAID 1 mirroring for critical data or separate OS and application storage for increased reliability.

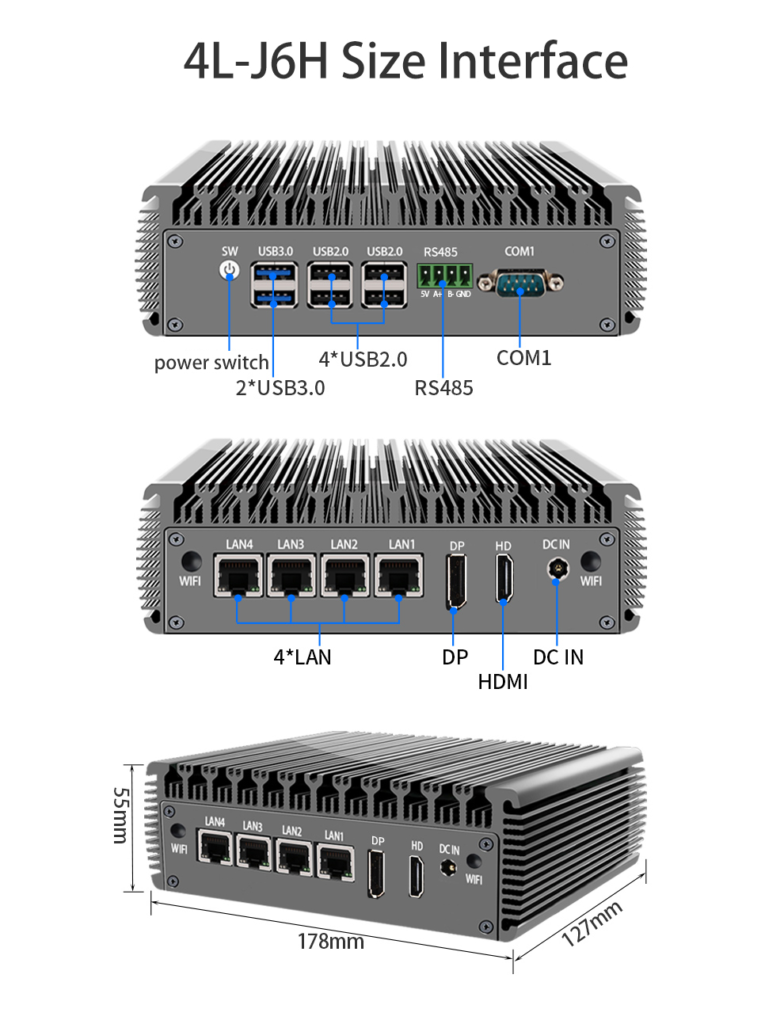

Connectivity and I/O Flexibility

Automation systems often require a mix of digital and analog I/O, serial ports (RS-232/485), and real-time fieldbus interfaces. Next, we’ll determine if your application requires high-speed Ethernet, Wi-Fi, or even 4G/5G modules for remote monitoring. Additionally, if you need synchronization with PLCs and industrial sensors, we can integrate industrial protocols, such as Modbus TCP, PROFINET, or EtherCAT, into your industrial mini PC.

For increased expansion flexibility, we use models with mini-PCIe or PCIe x1 slots to add specialized I/O cards or vision capture modules. In addition, many of our industrial mini computers feature GPIO interfaces, allowing users to connect sensors and actuators directly, which cuts the need for bulky external I/O racks.

Ensure industrial mini PCs are rugged and environmentally adaptable.

Industrial mini PCs must be able to withstand harsh environments, so we consider their operating temperature range, vibration and shock resistance, and ingress protection (IP) rating in custom designs. For example, an indoor automation unit may only require an operating temperature of -10 to 60 °C, while an outdoor photovoltaic power plant requires an operating temperature of -40 to 75 °C; in addition, an IP 54 or IP 65-rated chassis is dust and splash-proof and can be installed on the factory floor or in outdoor cabinets without an additional enclosure.

At the same time, corrosion-resistant materials and conformal-coated motherboards protect the electronics from moisture and chemicals. We also utilize industrial mini PCs with fanless cooling architecture to eliminate moving parts that can fail due to dust intrusion or high vibration.

Power Input and Energy Efficiency

Powering automation equipment often involves non-standard voltages and backup power requirements. Therefore, when we customize it, we ensure that it supports a wide range of DC inputs. In addition, some models that support Power over Ethernet (PoE) simplify the wiring of networked sensor arrays. At the same time, engineers can select low-power industrial mini PCs to cut heat generation and reduce UPS capacity needs.

In addition, our industrial mini PCs feature built-in surge protection and explosion-proof designs for traffic automation and energy management systems. Operators can also configure controlled shutdown scripts to manage unexpected power outages. By matching power compatibility and energy efficiency with your automation ecosystem, we help you minimize infrastructure complexity.

Software Compatibility and Lifecycle Support

We understand that automation platforms are constantly evolving and require regular security patches, driver updates, and operating system upgrades. Therefore, during the design process, we will also confirm that the industrial mini computer you choose supports the operating system you need, such as Windows 10 IoT, multiple Linux distributions, or real-time operating system kernels. At the same time, we recommend using remote management tools like Intel® AMT or existing out-of-band agents to apply updates without physical device access. In addition, secure boot and TPM modules ensure that only authorized software runs at boot time, thereby enhancing network security.

Designing an industrial mini pc that meets your needs

When designing an industrial mini pc for your custom automation needs, we will conduct a comprehensive assessment of performance requirements, connectivity, and other aspects. We will communicate with you to confirm the required processing power, memory, storage, I/O flexibility, ruggedness, energy efficiency, and supplier services. Ultimately, we design an industrial mini pc that balances these factors and provides reliable, scalable, and secure performance.