Buyers from various industries often ask a variety of questions when purchasing a fanless mini PC. These questions are typically driven by a range of specific considerations, including sustained cooling performance, dust and vibration resistance, I/O and expansion needs, software and driver support, installation and certification requirements, and more. To better address these concerns, this FAQ guide summarizes these considerations into clear answers, helping you decide between off-the-shelf models and custom fanless mini PC designs when your project requires a unique interface, branding, or certifications.

Performance, Thermal Management, and Processor Selection for Fanless Mini PC

Buyers often ask a range of questions when purchasing a fanless mini PC, such as performance thresholds and how passive cooling affects sustained throughput: “What’s the maximum CPU I can run in a fanless chassis before throttling becomes unacceptable? Do I need a low-power SoC or a desktop-class processor?” You should choose a processor based on your expected sustained workload and environmental conditions. Low-power Atom or Celeron-class SoCs are well-suited for lightweight tasks, consuming only 6-15 watts and experiencing minimal throttling in a sealed aluminum enclosure.

Compute-intensive workloads, in contrast, benefit from more powerful Intel Core or AMD Ryzen Embedded processors. Buyers also ask: What’s the duty cycle? If your application experiences bursts of high loads followed by long periods of idle time, a higher TDP chip in a fanless mini PC will generally work well, as the average thermal load remains manageable. However, for sustained peak loads, it’s better to choose a lower TDP SKU or ensure the enclosure and mounting surface are rated for adequate cooling.

Reliability, Lifespan, and Maintenance of Fanless Mini PC in Harsh Environments

Buyers often ask, “How reliable are fanless systems compared to fan-cooled mini PCs?” Fan-cooled systems generally offer better reliability than fan-cooled designs because they eliminate the moving parts that are often the first to fail: the fan and its bearings. This advantage is even more pronounced in dusty, oily, or highly humid industrial environments. However, the reliability of a fanless system depends critically on system sealing, thermal design, and the selection of components. To achieve a long MTBF in a rugged fanless mini PC, choose a model with solid-state storage (NVMe or SATA SSD) rather than a mechanical HDD.

If the environment is subject to corrosive gases or heavy particulates, choose the optional PCB conformal coating. Furthermore, for production-critical deployments, plan for three key areas: a spare parts inventory, regular health checks, and a replacement policy tied to the manufacturer’s warranty and component end-of-life dates. Periodic maintenance is typically minimal: as long as drive and memory wear indicators remain within specifications, regular cleaning of external surfaces and ensuring adequate cooling from mounting points are generally sufficient.

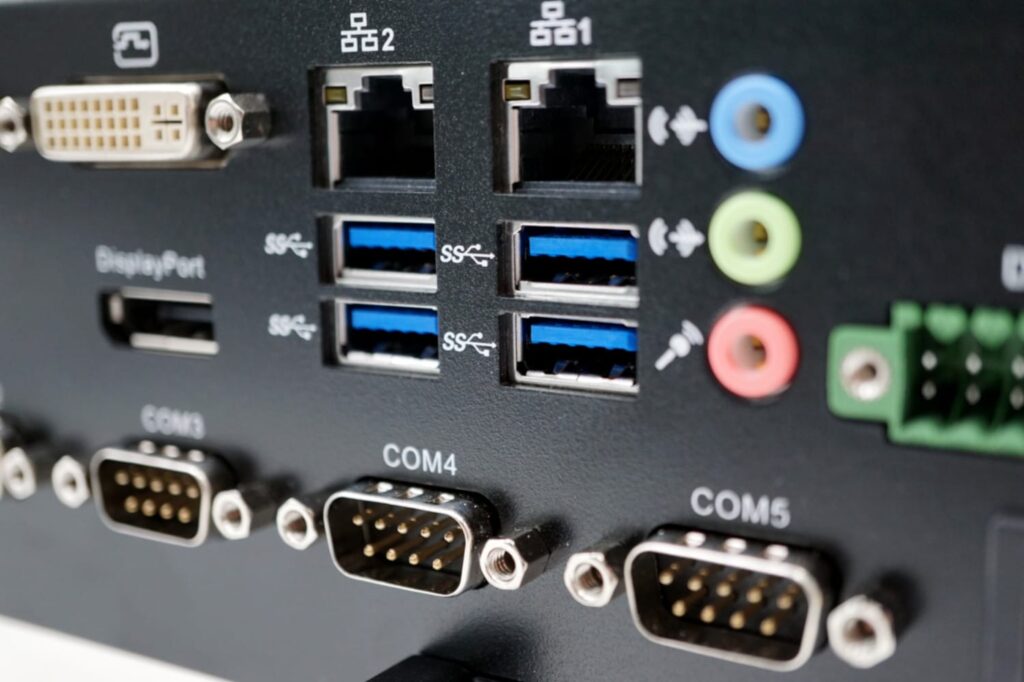

Is the I/O, connectivity, and expansion suitable for a variety of uses?

A common question is, “Does a fanless mini PC support my I/O stack—COM ports, multiple monitors, PoE, 4G/5G, or a discrete GPU?” The answer depends on the chassis size and target market. Small fanless mini PCs excel in a solid I/O mix, offering multiple USB ports, dual HDMI/DP outputs, Gigabit Ethernet or dual Gigabit Ethernet network cards, and optional M.2 slots for NVMe and cellular modems.

If you’re in industrial automation, you often require RS232/RS485 or DIO. Most mini PC vendors offer configurable models with soldered or modular COM ports and independent power supplies. For advertising applications like digital signage or multi-display kiosks, ensure the platform supports the number and resolution of displays you need and has validated GPU or iGPU drivers for continuous video stacking. Also, for edge AI and high-throughput I/O, consider PCIe expansion. Some larger fanless mini PCs include internal PCIe x4 or x8 slots for NVMe RAID cards or low-profile accelerators. However, note that adding accelerators increases cooling requirements and may exceed the design’s budget for simple passive cooling.

Customization, Software Support, BIOS, and “Custom Fanless Mini PC” Options

Off-the-shelf fanless mini PC models are fast to deploy, cost-effective for everyday needs, and typically come with tested drivers, BIOS, and warranties. They usually include a standard operating system image (Windows 10/11 or a Linux distribution) and a remote management agent. However, some users require specialized security features, unusual I/O, or an OEM-branded enclosure with custom paint and labeling, making custom designs more attractive. Customization can range from pre-loading and locking secure BIOS configurations and operating system images to creating custom carrier boards with integrated fieldbus interfaces or redundant power inputs for mission-critical systems. Minor modifications (such as branding stickers, BIOS settings, pre-installed software, or custom cables) can be inexpensive and quick. However, hardware-level changes require non-recurring engineering and longer lead times.

Mounting, Environmental Ratings, and Certifications

For mounting, fanless mini PCs often come with VESA mounts for rear monitor mounting, DIN rail kits for cabinet/rail mounting, or flange brackets for flat-surface connections. For self-service kiosks, consider tamper-resistant security screws and lockable enclosures. Environmental ratings are also crucial for some users. Many fanless mini PCs only support commercial indoor use, but enterprise and industrial models provide wider operating ranges and include optional conformal coatings, which users may require for humid or dusty environments. For outdoor or washdown environments, users need enclosures rated IP65/67. This increases costs and may require a separate external mounting enclosure rather than a bare chassis. For regulatory compliance, manufacturers must ensure that exportable electronics meet CE and FCC certifications, while also adding local standards (KC, RCM, EAC) as applicable. For critical infrastructure projects, suppliers must provide evidence of EMC testing and industry standards (such as the EN 61000 series).

Key Considerations When Purchasing a Fanless Mini PC

We’ve summarized some of the key considerations most buyers face when purchasing a fanless mini PC. Match the processor and thermal design to your ongoing workload and environmental conditions to avoid performance degradation; prioritize solid-state storage, conformal coating, and sealed enclosures for increased reliability in harsh or dusty environments; pre-validate I/O, display, and expansion requirements; and confirm mounting options, environmental ratings, and regulatory certifications for your deployment. So in short, you should have precise specifications when purchasing, require suppliers to publish thermal and reliability data, and only choose customization when it can significantly reduce integration risk or life cycle costs. This will reduce surprises, shorten production time, and ensure predictable field performance.